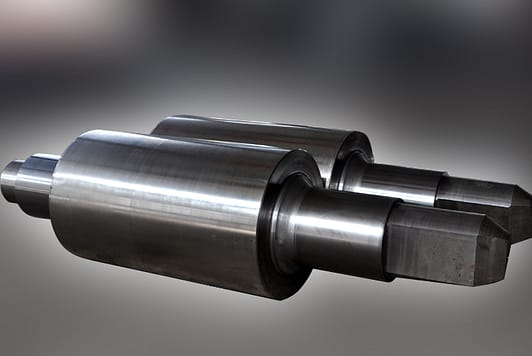

Roller Shaft

Main materials: alloy steel, carbon steel, stainless steel

Forging type:open die forging

Weight range: 1000-10000 kg

Diameter: 80-2000mm, Max length: 10m

Application: used for steam turbine for thermal power generation

QA DOC: chemical composition report, mechanical properties report, UT report, heat treatment report, dimensions check report

Inspection: in-house and by the third party

Contact us for more information on how this product can help you with your unique requirements.

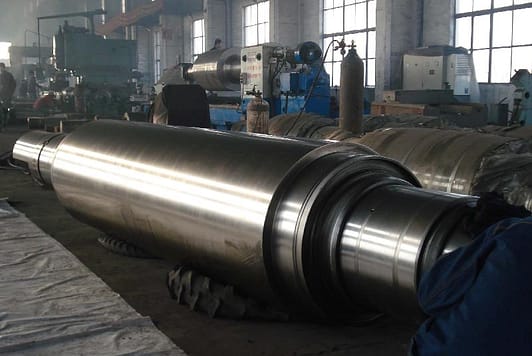

High chromium cast steel roll is manufactured by centrifugal casting process with high-Cr steel as the work later and nodular cast iron as the core, the material of work layer container 8-15% chromium, 1.0-1.8% carbon, as well as some alloyed elements such as molybdenum, nickel, vanadium etc. Through rational chemical composition allocations, normalized and tempered heat treatment, the final matrix can be controlled as tempered troostite, tempered sorbite, needle-liked bainite and some discontinuousM7C3 carbides.

Because of the existence of chromium matrix and fine carbides, the high or-steel possesses excellent thermal cracking and wearing resistance. This kind of rolls could be used widely, especially in the roughing stands of hot strip continuous rolling mills.

We are supplying the finest quality range of forged rollers, which efficiently cater to the demands of several industries. Our rollers are constructed in numerous sizes, length, and diameter that efficiently meet the quality standards and norms. We test these forged rollers on different guidelines to assure its superior functioning for a longer time period. We provide our product range at most reasonable prices.

Production Process

Application