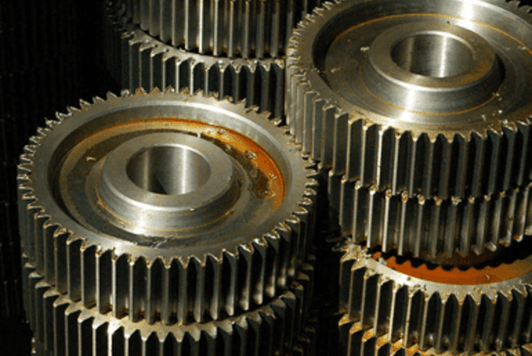

Spur Gear

Product Name: Spur Gear

Application:Mechanical transmission parts

Material:According to customer's requirements.

Standard:ANSI,ASTM,ASME,API,JIS,DIN,BS,EN,KS,UNI,SABS,GOST.

OD:Φ=2m

Tolerance:0.001~0.5mm

Machining accuracy: 6

MOQ:1 Pcs

Whether can be customized: Customized

Place of origin: Henan, China(Mainland)

Contact us for more information on how this product can help you with your unique requirements.

Teeth of Spur Gear is parallel to axis of rotation.

Can transmit power from one shaft to another parallel shaft.

Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with teeth projecting radially. Though the teeth are not straight-sided (but usually of special form to achieve a constant drive ratio, mainly involute but less commonly cycloidal),the edge of each tooth is straight and aligned parallel to the axis of rotation. These gears mesh together correctly only if fitted to parallel shafts.No axial thrust is created by the tooth loads.Spur gears are excellent at moderate speeds but tend to be noisy at high speeds.

Process characteristics of Spur Gear:

Blank-normalizing-roughing- hardening and tempering-rough gear hobbing/ rough gear shaping- carburizing-tempering-gear grinding-finishing-end product

Application: high precision, Precision reducer high precision.

Advantage: high synthesized mechanical properties, high internal tenacity, high surface hardness, good abrasive resistance

Material: 20Cr,20crmnti,20crnimo

The material of Spur gears usually we use alloy steel, carbon steel and so on or according to customer's requirements. And we can accept the standard by ASTM,ASME,API,JIS,DIN,BS,EN,KS,UNI,GOST...

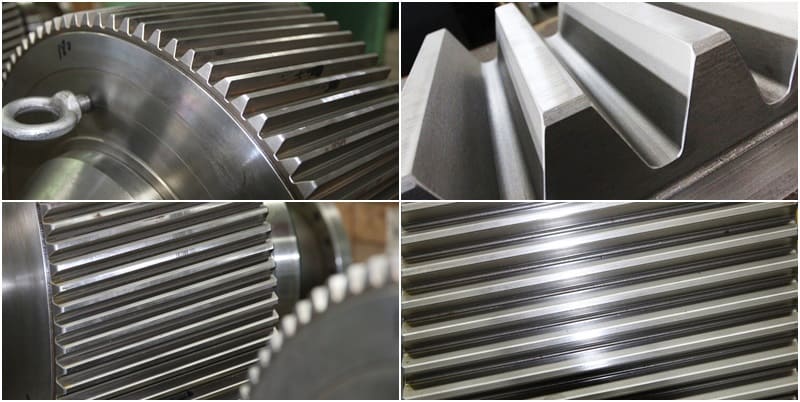

Products Details Show

Production Process

Why choose us?

Advantage

Symmen Gear adopts unique heat treatment to optimize the gear ring structure, to enhance hardness, wear resistance and impact force.

Symmen Gear uses high strength steel to cast gear ring and optimize rotary kiln to ensure the stability under long working time and prolongs service time.

Symmen Gear has a strong ability of producing steel casting and we can do mass production of gear ring in short cycle with large amount.

Leading Machining Equipment

Testing Equipment